I’m thrilled to have been invited to speak at the Sustainable Brands conference in Detroit in June on the topic of zero-waste everyday items. It’s great to see so many innovative choices out there these days amongst bamboo toothbrushes, shampoo bars, cleansing buds and keep cups, but why you may wonder, so little choice in intimates?!

As someone who came to bras as a frustrated customer, unable to find what she wanted out there in the market (for me this was initially non-wired bras in proper cup sizes and natural fibers, having been devastated by the lack of options when diagnosed with breast cancer 6 years earlier) it’s fair to say I had no idea how hard it was going to be. Often, the only person to attempt something so challenging is the person who has no idea how hard it will actually be, and who, once halfway through, cannot give up as they are already halfway through, no matter how much the universe seems to be against them!

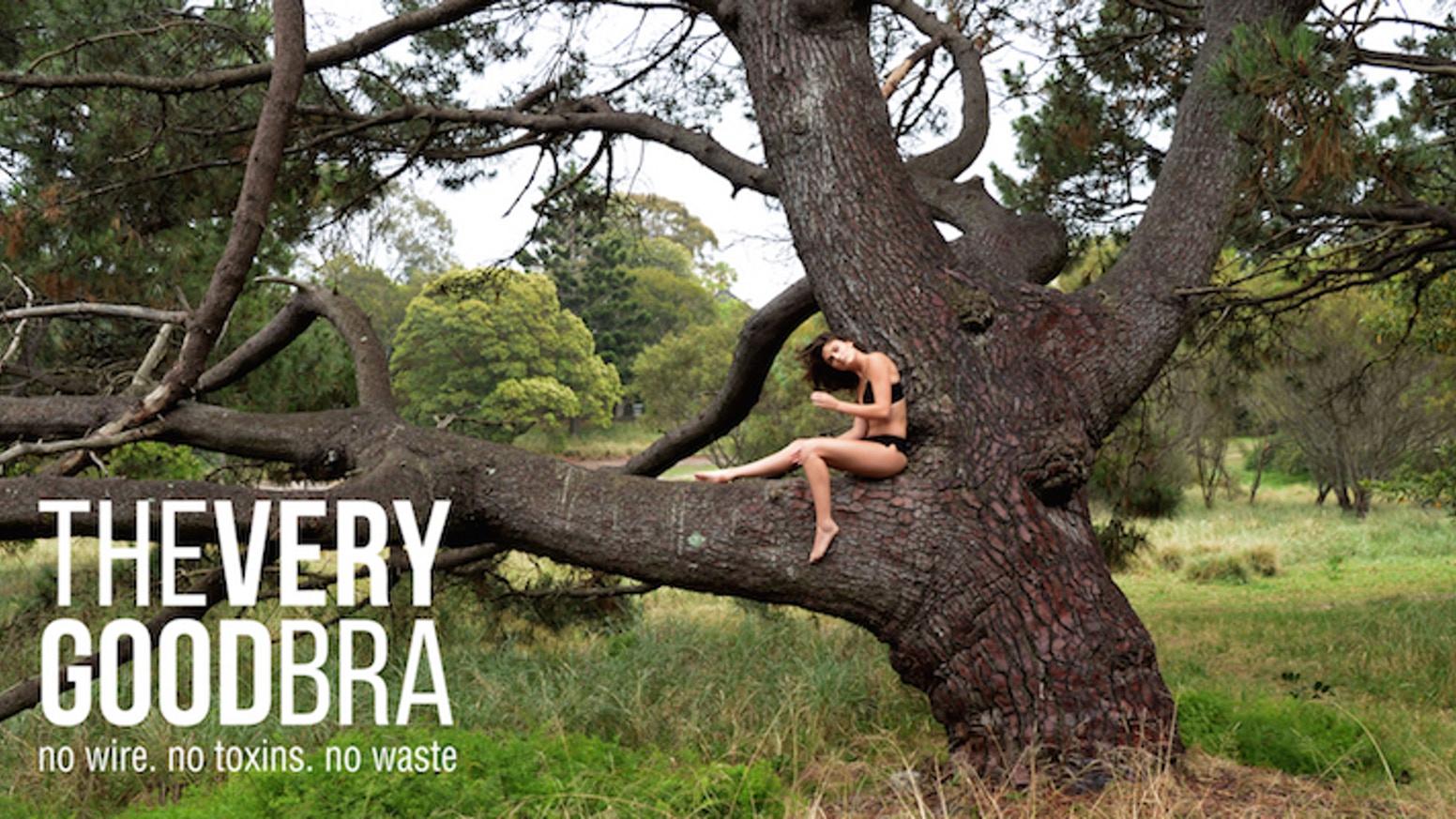

A bra may seem like a small, simple thing, but it has 9 individual components, which in the case of The very Good Bra had to be sourced from all corners of the earth, and a few which had to be re-invented and custom made. Enjoy this beautiful image of the finished product before I drown you with detail…

The components to a bra are as follows:

Fabric – easy right? but some needs to be rigid, some stretch, so how to do this without including spandex which is made from petroleum? I chose tencel for the body, in two different weights, because Tencel is one of the only fabrics that is truly traceable and verifiably 99% closed loop when made by Lenzing. We then had to design it so that the stretch in the knit gave us some of the flex we were losing without spandex.

Elastic – extremely challenging. Everything about elastic that makes it soft against your skin is synthetic, from the original nylon fabric to the processing. I scoured the world to find the only factory that could provide me with elastic made from natural tree rubber grown in FSC forests, knitted into organic cotton, and guess what? It costs more than 15 times more than regular elastic, and it’s so rough we actually enclose it in tencel around the body to make the bra softer against your skin.

Get News & Updates About SB'19 Detroit

Hooks and Eyes – My this was a problem. Our factory in China makes some of the most beautiful couture lingerie around, but China’s lingerie industry is probably only about 20 years old, and in their age, Hooks and Eyes have always been laminated and glued to make them strong and soft and durable. Many times I got them to try prototypes, and they would come back with ‘just a little glue’ which was just a little too much for my liking. I was stumped. The Kickstarter was starting in 2 weeks and I’d taken a year trying to work out this problem and had no solution. Then I figured out that as this was the way that bras were made before laminate and glue, I had to go back to the source of lingerie – Europe! They’d been making bras for centuries and who ever saw a laminate Hook and Eye in Madmen? After BEGGING a great old french factory, they agreed to make me a ‘tiny’ quantity of about 3 times the amount I needed, if I provided the organic cotton from the Netherlands for them to make them out of. We sent the fabric, they sewed it up – it worked and they agreed to take on the job.

Sewing thread – as above, everything has to be squeaky clean so I sourced the world’s most expensive tencel sewing thread (which costs about 15% of the overall cost of the bra) to sew with. Not only did the cost make mine and my factory’s eyes water, it also created a problem in bulk production, as it required different (slower) machines to make it hold properly – causing us another 2 week delay in production.

Labels – I tried many things for this. I was in love with a Cradle2Cradle approved pad printing process, which worked so well in the samples, right up to the point that I learned I needed to buy the entire machine for nearly USD$4000, find somewhere in China to house it, and someone to operate it. Thwarted again, and back to the Netherlands where I found a company that uses soy based inks to print on organic cotton. Prices astronomical of course, and particularly excruciating for the 26 individual bra size labels which could only be purchased in minimums of 100 each. To the 3 ladies who bought 30D bras, I sure hope you like them and will be back for more…

Foam padding – well, what can I say? We tried everything! My dear factory owner spent months sewing swatches of organic cotton and wool wadding into organic cotton to replace all that horrible polyester foam. It became the problem we had to solve. It’s fair to say we didn’t solve it. All options were too heavy, retained too much liquid, or were too lumpy. After a year of trials, we had to ditch that idea. If you are an A cup, we are very sorry, but we can’t give you more right now. We will keep looking.

Poly-bags – of course, everything that leaves the factory must do so in its own poly bag, with a bar code on it. Even though this won’t end up with the end-consumer, I couldn’t sleep at night knowing that I had used over 1000 poly bags for some undies and bras to get from mainland China to HK where they would be dressed in recyclable tissue and sent in a compostable mailer. Extensive research found me a company in Israel that makes poly bags from corn starch – awesome – just one catch – minimum quantity 10,000! Fortuitously, they had a bigger order going through that week which I could piggy-back off to get myself a measly 2000 for myself. Problem solved. Of course, they decompose after 6 months so I will be unlikely to use the other thousand or so. As it was my factory was pretty unimpressed with the sticky strips…

The packaging was easy, it was a delight to discover NoIssue for recyclable, branded tissue and labels, and The Better Packaging Co for those amazing ComPost bags. You gotta love New Zealand, they are almost as ahead of the game as the Dutch. I’ve seen more photos of TVGB packaging on Instagram than I have bras.

Are you still awake? If so, you’ll be relieved to know that that’s it. There are bits I’ve saved you from – channelling, cup re-enforcement, etc – safe to say there are a few other eco-wonders in there, but the above gives you the general idea of why this bra is really something special.

I look forward to sharing more detail on this complex, essential everyday item in Detroit in June.

About Stephanie

Stephanie Devine is the Founder and Owner of The Very Good Bra, the world’s first zero, post-consumer waste bra in over 24 sizes. The bra was launched via Kickstarter in 2018, reaching 350% of its goal in 30 days. The bra took two years to develop and necessitated scouring the world to source, and custom make the trims specific to bra making. Prior to The Very Good Bra, Stephanie founded and ran Bras Without Wires for four years, bringing wire-free comfort to women of all sizes and shapes. It was during this time that she learned about the apparel industry, and realized that there was much more to be concerned about than wires.